Home Willkommen bei WUTRA

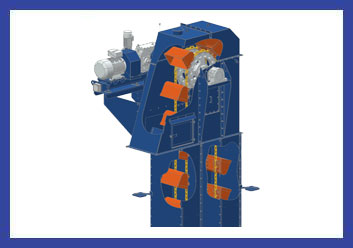

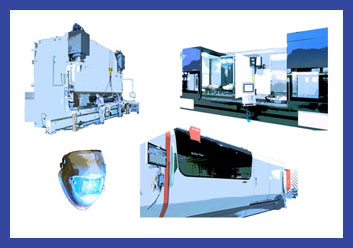

Die WUTRA Fördertechnik GmbH gehört als mittelständiges Unternehmen zur KAFRIL-Gruppe, die seit Jahrzehnten durch Wertarbeit weit über die Grenzen der näheren Heimat bekannt ist. Die WUTRA ist seit mehr als 130 Jahren mit ständig erweitertem Produktionsprofil im Bereich Förder-u. Prozesstechnik für Schüttgüter aller Art tätig und beschäftigt zur Zeit ca. 120 Mitarbeiter/innen. Eine eigene Konstruktionsabteilung im Verbund mit einer leistungsstarken Fertigung sichert dabei das hohe Niveau unserer Produkte. Unsere Montageabteilung sorgt für reibungslosen Aufbau, fachmännische Inbetriebnahme und Wartung der Anlagen.

WUTRA Fördertechnik GmbH bietet Ihnen von der Planung bis zur Inbetriebnahme eine fachkompetente Partnerschaft bei der Lösung Ihrer fördertechnischen Aufgabenstellungen!